Become an official partner of Infomir 3D Printing

Print prototypes and serial products in the shortest possible time and at the best price. We take care of the most challenging orders, helping you grow your business faster and continuously increase your client base.

Why working with us is a good decision

-

Unique Multi Jet Fusion technology

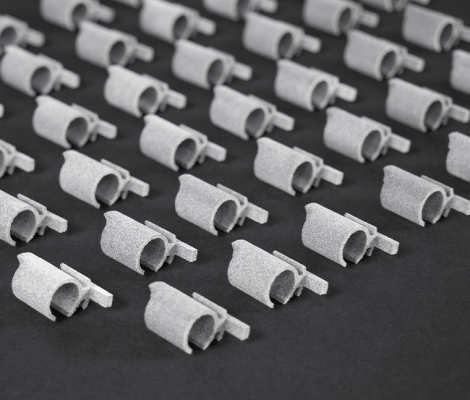

We use an HP Jet Fusion 5210 production line to print our products. This innovative technology enables us to manufacture prototypes and serial products with complex geometries without support structures or post-processing.

-

Partner price and terms

We offer special terms of cooperation to regular clients. Industrial printing from Infomir 3D Printing is a cost-effective alternative to FDM, SLS, SLA, and injection molding.

-

Orders delivered on time

Timely delivery is one of our priorities. We will give you an approximate lead time after receiving your request and assessing the print volume and current load. Our clients usually receive their orders within 5–7 days after sending a request.

-

Technical support and training

Infomir 3D Printing stays in constant touch with its clients. Our specialists are ready to help you arrange your order, answer your questions about the technology and material, and advise on preparing a 3D model for printing. Specifications and certificates are available if required.

Typical Partners

-

3D printing studios

We take orders for printing large batches of highly detailed products. Our line can print parts at 1,200×1,200 DPI with 80-micron layer thickness. It creates one-piece products with dimensions of up to 380x284x380 mm. Larger parts can be printed piece by piece and then glued together and sanded, resulting in a seamless finished product.

-

Manufacturers

Use the HP Jet Fusion 5210 printing line to start small-scale production. This way, you can save time and money on mold testing and introduce your finished product to the market in a short time. We can print up to 4 kg of finished products in one printing cycle (5–7 days).

-

Startups

Use the MJF technology to print prototypes and complex products. Our printer can print functional elements, parts within parts, and swivel joints. Prototype printing makes it possible to test the product design and adjust the source 3D model if necessary.

HP Jet Fusion 5210 line

Infomir 3D Printing uses the only HP Jet Fusion 5210 industrial 3D printing line in Eastern Europe. Our operators are fully certified by Hewlett Packard. HP Jet Fusion 5210 is the flagship of Hewlett Packard industrial printing equipment. It is more productive than its predecessors and can print high-quality products with minimal cost.

HP PA 12 polyamide

We use HP PA 12 polyamide as the printing material. This thermoplastic is resistant to moisture, ultraviolet light, and chemicals, making it suitable for printing cases, fixtures, gears, and even prosthetics. It is used in industry, medicine, and aerospace.

Coloring your products black, graphite, or gray

Finished products have a coarse gray surface, so Infomir 3D Printing offers additional coloring and graphite jetting services.

Products are immersed in a tank with dye using the first method or sanded with carbon and glass microspheres using the second one.

Both methods provide a high-quality coating quickly and cost-effectively.

About Infomir 3D Printing

Infomir 3D Printing is a project of Infomir, a Ukrainian IT company. It offers industrial printing services to manufacturers, startups, and 3D printing studios. The company uses a US-supplied HP Jet Fusion 5210 printing line that works several times faster than other powder printers.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you