3D printing for

manufacturers

We will launch small-scale production for you on the HP Jet Fusion 5210, an American 3D printing line, and we will help you quickly test the product design without at a much better cost than using molds.

How MJF technology is used in production

-

Fast prototyping

Before the product is launched into full-scale production, it is checked and tested. The product can then be modified: its shape or design can be improved. With 3D printing, the manufacturer does not have to spend money and time on making a mold.

-

Small-scale production

Additive manufacturing means you can make any number of products—from one to several hundred. Print a drone case or a batch of car spare parts, anything is possible. The customer gets finished products within a short time: the printing cycle lasts 3–5 days.

-

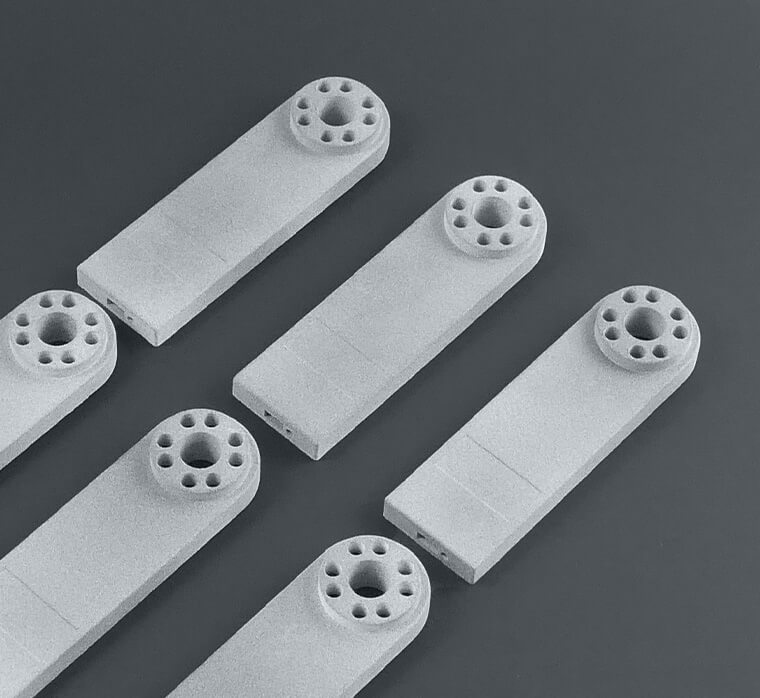

Manufacturing complex parts

The HP Jet Fusion 5210 printing line allows for the creation of complex products without support materials; during printing, the voids are filled with material powder (HP PA 12, PP, or TPU), which is subsequently removed. This makes possible the production of functional parts, hinged joints, and products with complex geometries.

Partners will get a 20% discount on the total order amount

There is a permanent 20% discount for official partners. To get the discount, fill out the form and tell us about your 3D printing studio. Once we have processed your request, you will get a discount on the first and all subsequent orders.

The benefits of 3D printing

-

01

Faster than molding

You do not have to wait until the mold is made to launch production. The order and manufacture of the first batch of products takes several days. This saves the customer months in the early stages of production.

-

02

Fast market launch

It is difficult to create a perfect mold the first time due to possible errors in the 3D model. Errors can only be seen when the mold is ready and paid for. Industry 3D printing allows for vast improvements in the design without any financial risk.

-

03

Complex forms

Three-dimensional printing makes it possible to create complex, one-piece products: chains, hinged connections, and nested structures. Such products are seamless: you do not have to glue or solder them. Molding cannot do this.

-

04

It pays off when the production volume is up to 1,000 products

3D printing is cost-effective even for small batches. The manufacturer does not spend money on the manufacture of a mold and is not forced to redo it: production is profitable from the first batch.

-

05

Benefits of complex geometry

MJF allows the making of products with corrugated, porous, or perforated surface. This gives you more design options and capabilities to create both lightweight and durable structures.

-

06

Helps to find out the demand

You can check the product relevance while producing a small batch before launching the product into full-scale production. This will help the manufacturer to find out how interested buyers are, and whether it will be high in demand on the market.

-

07

Customization and post-processing

Products can be equipped with a unique logo, QR code, or an inscription. MJF technology allows the creation of completely isotropic products, so they are easy to process: dye and sand, and putty.

-

08

Convenient for product development

During the development phase, 3D printing allows you to quickly create prototypes, test them, and, if necessary, refine the product design or shape. You can get an updated prototype in 3–5 days.

FAQ

-

How long does it take you to fulfill orders?

A printing cycle takes 3–5 days. It includes building, cooling, and sandblasting.

-

What materials do you use for prototype building?

We print products from Hewlett-Packard proprietary materials: HP PA 12 polyamide, polypropylene (PP), and thermoplastic polyurethane (TPU). All of them are stronger and more chemically resistant than ABS and photopolymers.

ABS plastic melts at a temperature of 105°C. The melting point for HP PA 12 is 187°C, for PP it is 138°C, and for TPU it is 192°C. All of these materials are resistant to stress, vibration, chemicals, and water. They are used in the automotive, industrial, medical, and other fields.

The strength of the product depends not only on the material but also on the thickness of its walls. Follow our guidelines on how to prepare models from HP PA 12, PP, and TPU for printing to obtain the best results.

-

What are the maximum dimensions?

The printer has a build area of 380 × 284 × 380 mm.

If the model is larger than that, it is divided into parts and then assembled. This is how car bumpers and dashboards, architectural models, and sculptures are created. Our online calculator doesn’t divide models into parts, so only project managers can adequately assess the build price in such cases.

Send your oversized models to our manager:

Tel.: +38 (099) 075 59 95Telegram: https://t.me/infomir3dprinting

Email: 3dprint@infomir.com

-

How precise is MJF printing?

The HP Jet Fusion 5210 applies polymer in layers of 0.08 mm with a horizontal resolution of 1,200 × 1,200 DPI and a margin of error of 0.08–0.1 mm.

The horizontal resolution is based on the maximum precision of the X- and Y-axis movement of the printhead. The higher the number, the higher the level of detail. Vertical resolution is the minimum thickness of the polymer layer applied in one pass. The thinner the layer, the smoother the build’s surface is.

-

Do you do post-processing?

The completed builds only undergo sandblasting to remove surplus polymer. Optionally, they can also be colored.

We use two coloring methods:

- Dyeing. The application of color by immersing the item into a reservoir of dye.

- Graphite blasting. Similar to sandblasting, but with glass and graphite as an abrasive material. It gives the item a dark-gray color.

Dyeing and blasting are inexpensive and efficient ways of getting a high-quality finish.

Available colors: graphite, black, and gray. Other finishes will soon be made available. -

How do I pay for my order?

You can pay for your order once our manager clarifies all the details with you. Infomir 3D Printing fulfills orders only on pre-paid terms. You can pay for your order with a PrivatBank card or cashless payment.

For cashless payments, we need the client to submit their registration certificate, VAT payer’s certificate, and banking details. After the order is paid for, we will deliver the finished items together with an invoice.

-

Do you provide 3D scanning/modeling services?

Our specialists work with finished models. If you need a model developed or 3D scanned, we can refer you to our trusted partners.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you