Multi Jet Fusion powder 3D printing

Multi Jet Fusion is a type of 3D printing technology with using powder. It is perfect for prototypes and full-scale production and ensures low-cost products. MJF makes small batches much cheaper than products made using molds.

The 3D printer techniques, and in particular MJF, help to create durable parts and obtain batch-production quality without molds. It does not need support materials, so the products are easier to design and process.

Infomir 3D Printing carefully checks the quality of every printed part. Customers receive the parts of the required dimensions and assemblability.

People choose Multi Jet Fusion for quality and detail

-

Durable and reliable products

Finished parts neither crack under load nor change their properties under the influence of ultraviolet radiation. The technology is used even in the aerospace industry.

-

Batch-production quality without molds

Multi Jet Fusion is the main competitor to injection molding. Timeframes are reduced from months to days: the technology allows you to print hundreds or even thousands of parts at the same time. No alternative technology can provide such precisely finished products as with MJF printing.

-

No support materials

MJF printers print without support materials. This helps to create complex structures and time for 3D modeling and post-processing of parts.

-

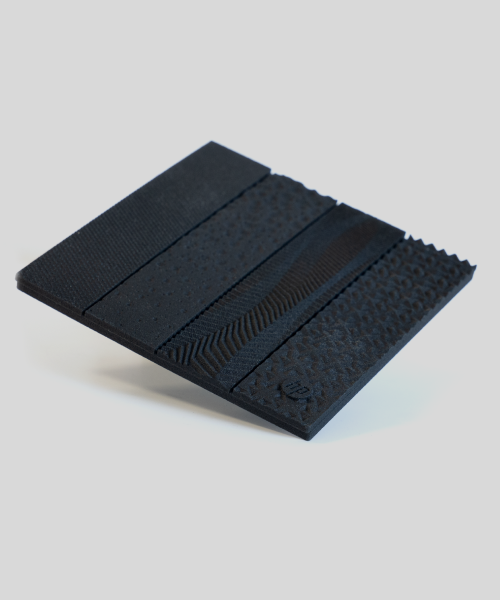

1,200 DPI detailing and 100-micron tolerances

Our printer prints with a 1,200 DPI horizontal resolution and an 80-micron layer thickness. We provide a tolerance grade from 5 to 8 and tolerance limits from 100 to 250 microns.

The materials used in the production process

-

Material: PA 12 polyamide

HP High Reusability PA 12 is a tough thermoplastic for prototypes and finished products. It is UV and chemical resistant, and non-flammable. It is used to print cases, mounts, gears, prostheses, and other parts. HP PA 12 is used in manufacturing, medicine, and even aerospace industries.

-

Material — PP (polypropylene)

Polypropylene (PP) is a durable thermoplastic with a wide range of applications. The material is resistant to chemicals and has a low density. Its light weight and robustness make PP the ideal material for 3D printing a wide variety of parts and products.

-

Material — TPU (thermoplastic polyurethane)

Thermoplastic polyurethane (TPU) is a unique material that combines strength and flexibility. It is widely used in 3D printing to create flexible, durable, and abrasion-resistant parts.

We use the HP Jet Fusion 5210 line

Infomir 3D Printing is the only company in Eastern Europe to have an HP Jet Fusion 5210 line. Our specialists have also received Hewlett Packard certificates in Spain.

HP has several MJF solutions but HP Jet Fusion 5210 is the most advanced one. Compared to the 4200 series, our line offers better performance and quality at the lowest cost.

We can create up to four kilograms of parts in one printing cycle.

Each layer is printed in four steps

-

1. The powder is spread over the working surface.

-

2. The printer applies the bonding material selectively.

-

3. The heating element fuses the layer with infrared light.

-

4. The layer hardens, and the process is repeated.

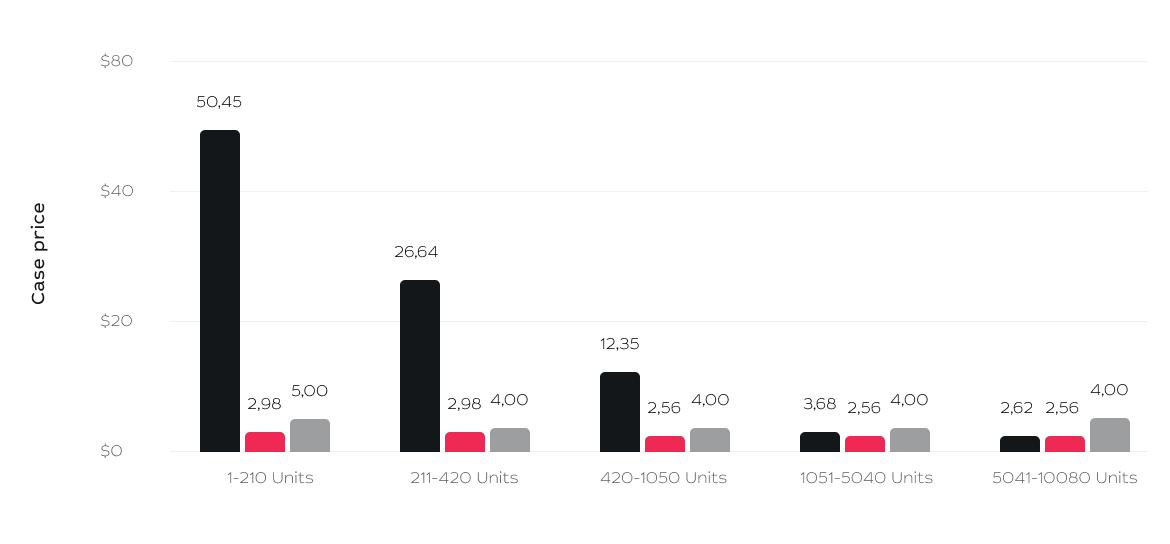

The technology is five times more profitable than injection molding in small batches

Injection molding and molds are not suitable when you need to produce only a small amount of products. 3D printing solves this problem. Take for example a Bluetooth transmitter case, the device that Infomir released in early 2020.

We create parts in small batches for customers at a price close to that of batch-production.

-

Dimension:

40 × 40 × 10 mm -

Amout:

With a circulation of 1,000 units, a printed case is five times cheaper than a molded one.

You can use a calculator to figure out how much it will cost you to print your 3D model:

Calculate the cost

- Molding (up to 10,000 copies)

- Multi Jet Fusion 3D printing

- Industrial FDM printing (first draft)

Hewlett Packard line runs 24/7

-

1. Visualization and getting the printer ready

3D models go into Build Manager, a software used to turn the model into printer commands. Then a box with powder is placed into the printer, and the line is ready to start.

-

2. Printing

The software sends commands, and the HP Jet Fusion 5210 fuses the products layer by layer, exposing them to high temperatures and using bonding material. The entire working area heats up, that’s why all products are printed simultaneously.

-

3. Cooling

For the parts to retain the desired properties, they are cooled gradually. The process takes 15 to 30 hours. Meanwhile, the printer starts printing another batch.

-

4. Cleaning

Products are cleaned of powder residues. The parts are then ready for use. They can also be dyed black, graphite, or gray if need be.

Painting Products Black

Without additional processing, the details have a gray, rough surface. Therefore, the products can be painted black after printing. This is an inexpensive and fast way to get parts with a quality finish.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you