3D printing for start-ups

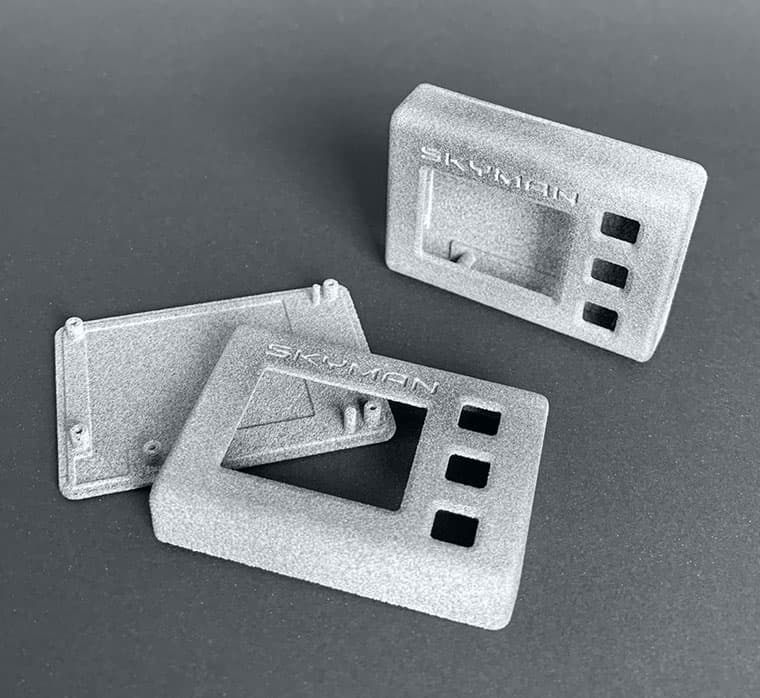

We transform 3D models into functional prototypes and demo products. Our printed products are of batch-production quality: they can be presented to investors, showcased at industry exhibitions, or used to start crowdfunding campaigns.

How start-ups use MJF Technology

-

Prototype without equipment investments

MJF Technology enables you to print prototypes before starting full-scale production. You can test the design on finished products and, if necessary, correct the 3D model. This means manufacturers no longer have to spend time and money creating new injection molds.

-

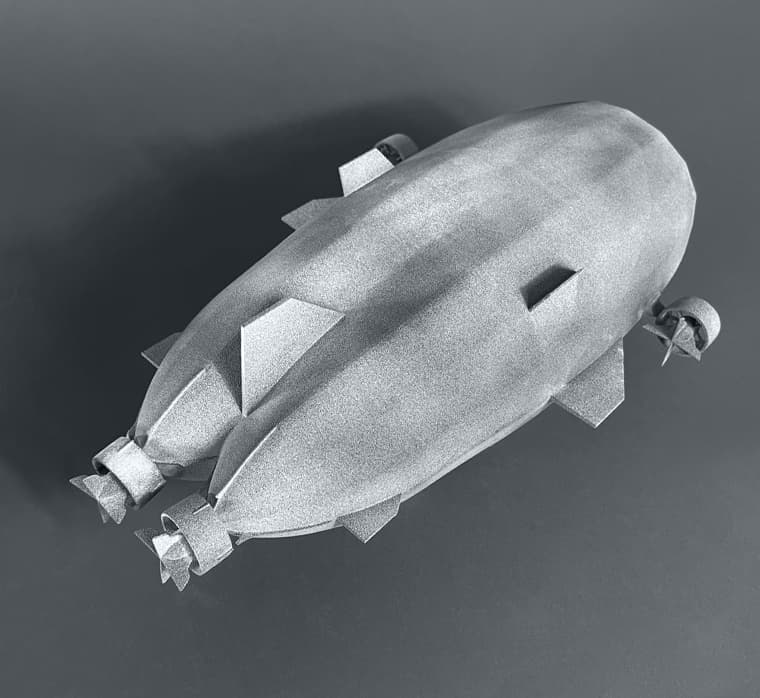

Complex constructions

Using 3D printing, you can make products of complex geometrical construction without support materials. MJF Technology makes it possible to create functional items, hinge joints, and parts within parts.

-

Finished products

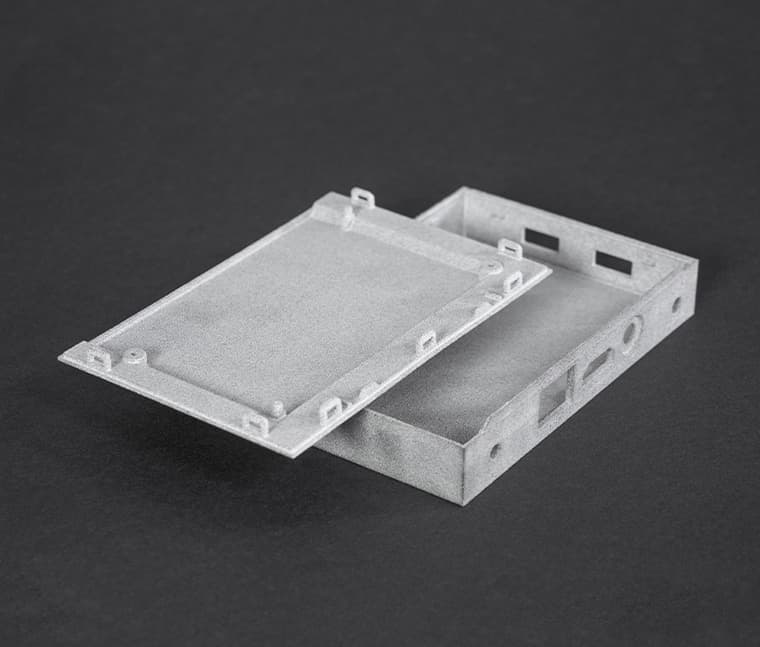

HP Jet Fusion 5210 creates highly detailed finished products. Printed models are smooth, durable, and free of jagged textures. The products are ready to use and don’t need additional post-processing.

Partners will get a 20% discount on the total order amount

There is a permanent 20% discount for official partners. To get the discount, fill out the form and tell us about your 3D printing studio. Once we have processed your request, you will get a discount on the first and all subsequent orders.

The benefits of 3D printing

-

01

Fast

In 3D printing, the application and sintering of each product layer takes only a few seconds. Thanks to this, one print cycle lasts no more than a day. The customer can therefore get a finished product within three days.

-

02

Finished products

It is the contractor that performs all stages of production for printing using MJF Technology. All the customer has to do is provide a 3D model and pay. Products can be used straight out of the box.

-

03

Complex forms

3D printing is used to make products of various shapes and constructions. For example, nested parts, chains, hinge joints, and tubular elements.

-

04

Easy-to-make products

MJF Technology enables the printing of lightweight and durable parts. To do this, they use structures with a corrugated, porous, or perforated surface.

-

05

Post-processing

Finished products can be refined: drilled, sawn, and ground. The print material is durable and does not crumble under mechanical stress.

-

06

Print accuracy

Printed products fully comply with the 3D model parameters. The parts’ visual identity does not depend on the print volume.

-

07

Demand forecast

You can find out the demand for products by producing a small batch of them. This can help manufacturers estimate the demand for a new product.

-

08

Payback

3D printing is cost-effective even when several items are made. A start-up doesn’t have to invest in an expensive mold. It can get profit from the very first printed batch.

FAQ

-

What safety certificates does the PA 12 material have?

We guarantee that our printer’s output is safe. The PA 12 polyamide contains no heavy metals, phthalates, and bisphenol A, meaning that it’s safe enough even for toys.

Besides, it meets all European and American biocompatibility and fire safety requirements.

-

How fast does HP Jet Fusion 5210 print?

At full capacity, printing takes no more than 12.5 hours. If the building volume is only partially filled, the printing time becomes proportionately shorter.

The build cannot be removed from the station immediately after its completion, as the material’s mechanical properties will suffer from flash cooling. In Fast Cooling mode, it takes 4 hours for the build to cool entirely, and in Natural Cooling mode it takes up to 30 hours. Cooling is done in a separate module, so it has no impact on the printing performance. -

Do you provide 3D scanning/modeling services?

Our specialists work with finished models. If you need a model developed or 3D scanned, we can refer you to our trusted partners.

-

How do I place a 3D printing order?

Upload your 3D model to our online calculator and input the item size and quantity to get a quote from us.

The minimall order price is UAH 500. Also, don’t forget to add your contact details and project description for our manager. Once your order is paid for, we will print and ship it with Nova Poshta. Special terms apply for large and recurring orders.If you need an oversized model printed or the size of your file exceeds 25 MB, contact our manager for a more precise price estimate:

We work with individuals, legal entities, and sole entrepreneurs.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you