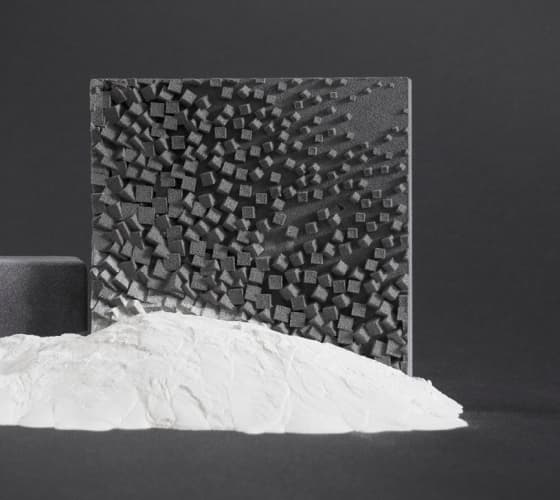

HP PA 12 polyamide for 3D printing

HP High Reusability PA 12 is a tough thermoplastic from Hewlett Packard. It is used for printing prototypes and finished products in the production and medical industry.

In terms of characteristics, 3D printing polyamide HP PA 12 is superior to ABS plastic and photopolymers. Polyamide is biocompatible, non-combustible, as well as UV and chemical resistant. It is used to print mounts, parts, cases, and products with IP67 protection.

Reliable and safe material

-

Durable and resistant to chemicals

HP PA 12 products are designed to withstand drops, impacts, and static loads. Polyamide 3D printing is used to make durable cases, mounts, pipes, and car bumpers. Polyamide also retains its properties upon contact with fuel, oils, and solvents.

-

Biocompatible and heat-resistant

The fire safety and biocompatibility of HP PA 12 have been confirmed in Europe and the USA. The material is free of phthalates, bisphenol-A, and heavy metals. Toys, external prostheses, corrective insoles, and even respirators are printed from it.

-

Stronger than ABS and photopolymers

HP PA 12 outperforms ABS and photopolymers used in injection molding and 3D printing. The material does not delaminate and, unlike ABS plastic, it retains its strength under ultraviolet radiation.

-

Suitable for products with IP67 protection

Polyamide parts have high density and precise tolerances: the material is suitable for products with IP67 protection. It is used for printing sealed cases that can withstand dust, rain, and immersion in water to a certain degree.

High-performance physical characteristics

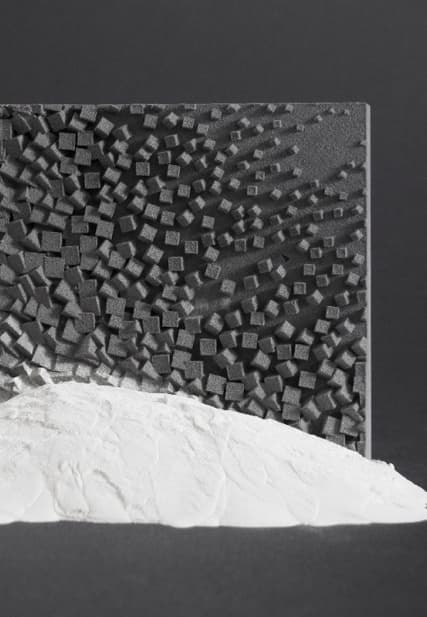

HP PA 12 parts have a gray surface. The layers are sintered tightly, so the finished products have high abrasion resistance and do not split. The material retains its strength with sharp variations in temperature and on exposure to ultraviolet radiation.

General properties

- Powder melting point (DSC) 187° C/369° F

- Particle size 60 µm

- Bulk density of powder 0.425 g/cu cm

- Density of parts 1.01 g/cu cm

Mechanical characteristics

- Tensile strength, max load, XY 48 MPa/6960 psi

- Tensile strength, max load, Z 48 MPa/6960 psi

- Tensile modulus, XY 1700 MPa/247 ksi

- Tensile modulus, Z 1800 MPa/261 ksi

- Elongation at break, XY 20%

- Elongation at break, Z 15%

- Flexural strength (@ 5%), XY 65 MPa/9425 psi

- Flexural strength (@ 5%)10, Z 70 MPa/10150 psi

- Flexural modulus10, XY 1730 MPa/251 ksi

- Flexural modulus10, Z 1730 MPa/251 ksi

- Izod impact notched (@ 3.2 mm, 23ºC), XYZ 3.5 kJ/m2

Thermal resistance

- Heat deflection temperature (@ 0.45 MPa, 66 psi), XY 175 ºC/347 ºF

- Heat deflection temperature (@ 0.45 MPa, 66 psi), Z 175 ºC/347 ºF

- Heat deflection temperature (@ 1.82 MPa, 264 psi), XY 95 ºC/203 ºF

- Heat deflection temperature (@ 1.82 MPa, 264 psi), Z 95 ºC/203 ºF

Resistant to water and chemicals

Products made from HP PA 12 retain their durability even if they are in contact with chemicals for a prolonged period. The material retains its properties when interacting with water, lubricants, solvents, petrol, and alkaline products.

There are almost no pores in the material, so it does not need epoxy resins to be made water-resistant. Sealed containers and pipelines are printed from it, capable of withstanding liquid pressure up to 20 atm.

Products made of polyamide are denser than water; therefore, even after immersion in water for 24 hours, they absorb no more than 5% of their own weight.

| Liquid | Resistance |

|---|---|

| Diluted alkaloids | ●●●●● |

| Concentrated alkaloids | ●●●●● |

| Hot water | ●●●○○ |

| Chlorine salts | ●●●●● |

| Alcohol | ●●●●● |

| Esters | ●●●●● |

| Ethers | ●●●●● |

| Ketones | ●●●●● |

| Aliphatic hydrocarbons (including gasoline components) | ●●●●● |

| Motor oil | ●●●●● |

| Aromatic hydrocarbons | ●●●●● |

| Toluene | ●●●●● |

| Unleaded gasoline | ●●●●● |

| DOT 3 brake fluid | ●●●●● |

| Chlorinated hydrocarbons | ●●●○○ |

| Trichloroethylene | ●●●○○ |

Safety certificates

Hewlett Packard polyamide is free of heavy metals, carcinogenic PAHs, phthalates, and bisphenol A, so products can get in contact with skin. Its biocompatibility is USP Class I–VI certified, and its content of hazardous substances is certified by RoHS and REACH, Ingredient Safety Statement, and PAHs Certificate.

UL 94 and UL 746A documents certify that polyamide is suitable for products that are not exposed to open flame. The material retains its strength even when heated to +120°C.

HP PA 12 is environmentally friendly. It does not need special storage and disposal conditions.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you