Industrial 3D printing services

We will print your 3D models on the HP Jet Fusion 5210, an American print line. We create prototypes and finished products in any quantity. We ship across Ukraine.

From prototypes to finished products

-

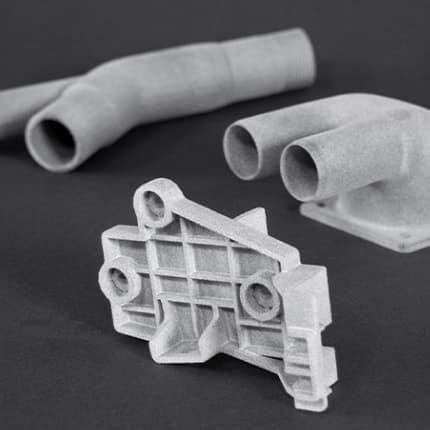

Prototypes

Assembled cases, mounts, prototype models, and device parts.

-

Medical products

Jaw and joint models, respirators, artificial ventilation adapters, and other equipment.

-

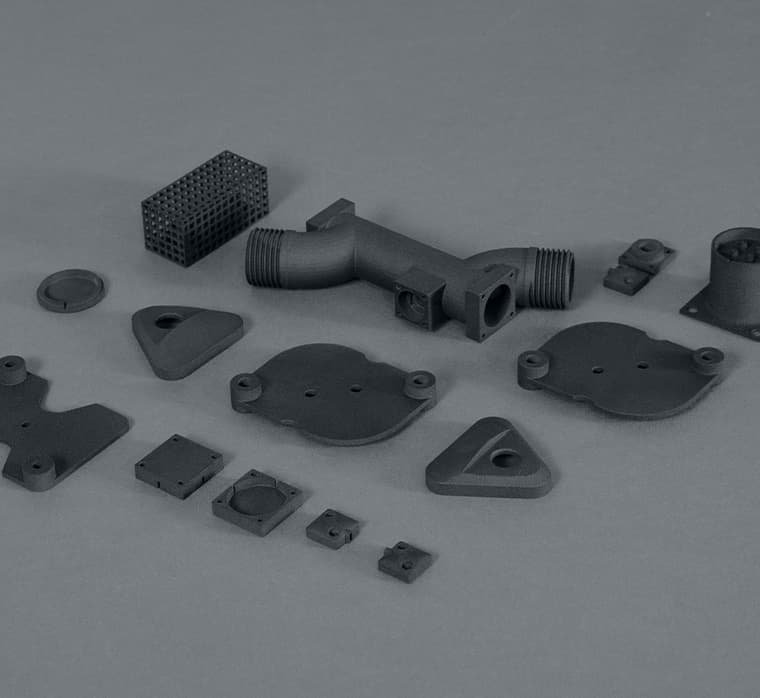

Functional parts

Functional mechanisms, cases, gears, fasteners, and tubes.

-

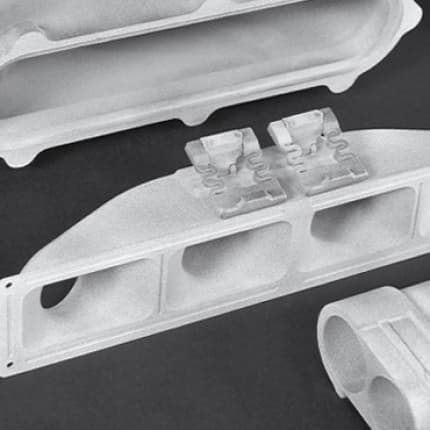

Ready-to-use products

Parts and finished devices, the processing quality of which is far from inferior to molding.

For different industries

-

Production

We help to check the product design and avoid problems with the molds. We launch full-scale production.

-

Medical industry

3D printing on demand helps clinics serve more patients, protect staff, and plan surgeries. Aligners and prostheses are made using models.

-

Start-ups

We turn 3D models into prototypes for exhibitions or presentations to investors.

-

3D printing studios

We carry out crucial orders for studios when there are high requirements for products, and they have to be printed quickly and in large quantities.

-

Car services

We print tools for garages and general car maintenance, as well as rare details and decorative elements.

-

Special projects

Architecture studios can create building models many times faster. MJF technology makes it easy to obtain complex parts.

We create parts for the repair of filming equipment, props for films, TV shows, and advertising.

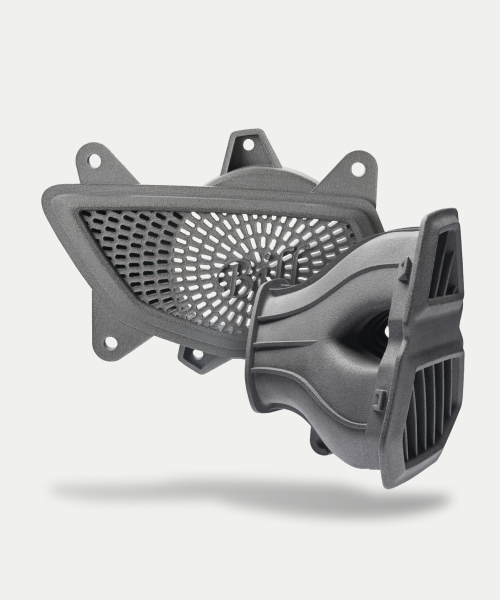

Multi Jet Fusion technology

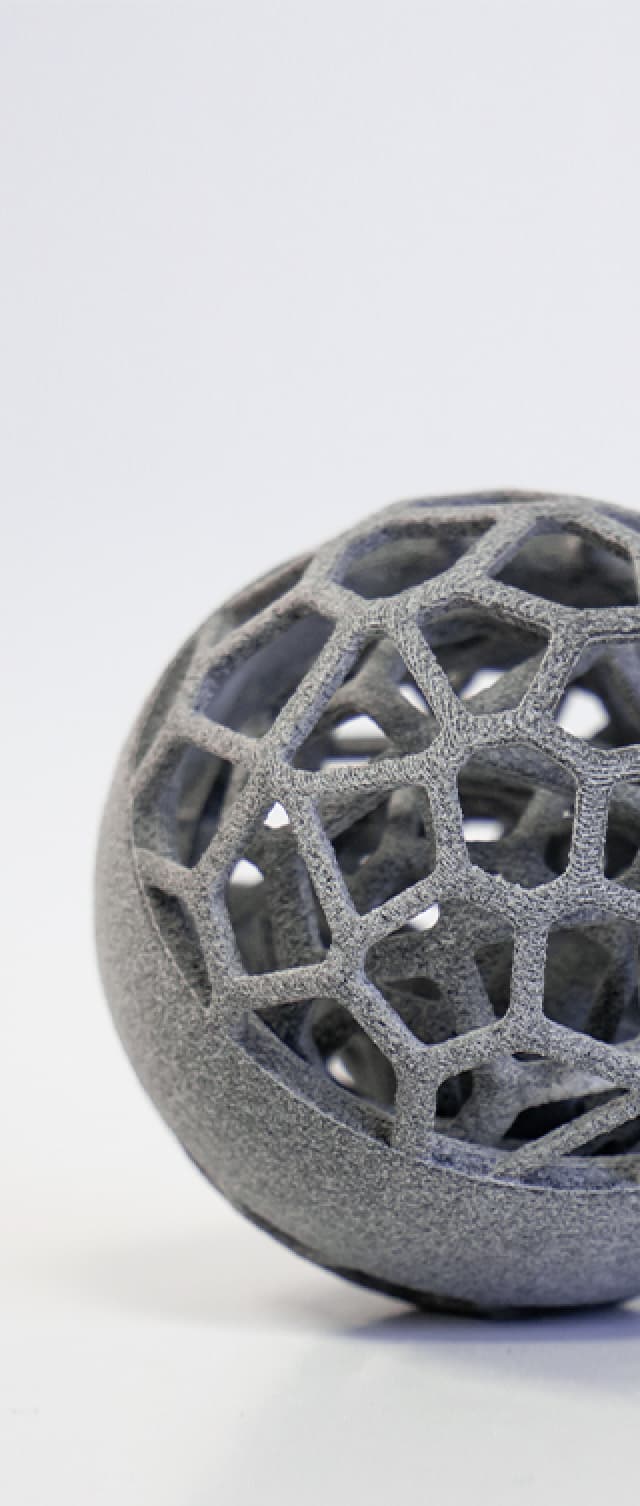

Multi Jet Fusion is a 3D printing powder technology. It can handle things that injection molding, CNC machines, and even other 3D printing methods cannot cope with. MJF is the go-to choice for robust and detailed prototypes and production samples.

-

1,200 DPI resolution and an 80-micron layer

The minimum layer thickness is 80 mm. The same thickness as a human hair. Coupled with a 1,200 DPI resolution, the result is high-precision products.

-

No support materials

Products printed using Multi Jet Fusion Technology do not require support materials. They have stable mechanical properties and a more detailed and smoother surface. The plastic is solid and does not crack. The finished parts are fully functional and do not have to be sanded or colored.

-

Saving time and money on molds

MJF technology makes it possible to test the product design before leaving the design-stage and beginning full-scale production. The finished product quality becomes more predictable. In small-scale production, the technology completely replaces injection molding.

-

For complex products and prototypes

The technology handles single-piece moving parts, nets, ducts, and nested structures. This is useful when only a single copy of the product is needed—for example, to print a device prototype or an internal organ model.

Material: PA12 (nylon)

We use PA 12 polyamide powder for printing. It is manufactured by Hewlett Packard.

Polyamide is stronger than ABS and photopolymers. While ABS plastic melts at +105°C, PA 12 does at +187°C.

The material is resistant to ultraviolet light, lubricants, petrol, and alkaline environments. Finished products made of PA 12 hardly absorb water and retain their durability even if they are used outdoors for a long time.

Polyamide is non-flammable, contains neither heavy metals, nor phthalates, nor bisphenol-A. Even toys are printed from it.

Material — PP (polypropylene)

PP is based on a thermoplastic polymer and is ideal for the creation of lightweight and durable products. The material is highly chemical resistant and has corrosion resistance and shock absorbing properties. These qualities make it an optimal solution for creating functional prototypes and parts and components affected by mechanical stress. The low density of polypropylene and its resistance to moisture allow for the printing of products that function in a variety of environments.

The material opens up new possibilities in the manufacturing of detailed, complex, and functional products, resulting in the improvement and optimization of manufacturing processes.

Material — TPU (Thermoplastic polyurethane)

3D printing from thermoplastic polyurethane is an innovative approach to creating durable and flexible objects with high printing accuracy. The material has unique properties suitable for functional prototypes and parts under mechanical stress. 3D printing with TPU provides highly detailed and malleable products, expanding the possibilities for creating complex shapes and structures. Parts printed with thermoplastic polyurethane are resistant to moisture and chemical compounds.

The material’s properties allow it to be used in the automobile, footwear, and textile industries, electronics, and medicine.

Painting Products Black

Without additional processing, the details have a gray, rough surface. Therefore, the products can be painted black after printing. This is an inexpensive and fast way to get parts with a quality finish.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you