TPU (Thermoplastic polyurethane) for 3D printing

TPU is a powder containing thermoplastic polyurethane for 3D printing with the HP Jet Fusion 5210 industrial printer. The properties of the material allow for the printing of resilient, durable, and chemical resistant products.

The powder is used for custom 3D printing on demand and the manufacturing of prototypes and functional parts in various areas, such as medicine, the automobile industry, electronics, and shoemaking.

Where the material is used

Printing using TPU allows you to adjust the rigidity of final products depending on the manufacturer’s needs. You can create parts with different levels of stiffness and flexibility, which makes the powder a multipurpose material for a variety of TPU applications in industry.

-

Automobile industry

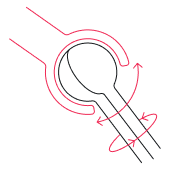

TPU enables the construction of flexible and durable parts for automobiles, such as seals, rubber gaskets, flexible tubes, and air branch pipes. These parts have good wear resistance and resilience to chemical influences, making them ideal for vehicle construction and repair.

-

Medicine

Flexible TPU components for medicine are used to make a variety of medical devices and prostheses, including custom orthotic insoles, cushioning inserts, pads, and other parts that provide comfort and physical support for patients.

-

Shoemaking

TPU is used to create footwear. The material’s qualities make it suitable for customized and comfortable soles, inserts, and other components for final products. The flexibility and resilience of polyurethane make it an ideal material for athletic footwear and outdoor activities.

-

Industry

TPU powder is used to create flexible parts and components for industrial equipment such as seals, gaskets, sleeves, and dust plugs. This improves functionality and reduces wear and tear on parts and components used in industry.

High physical characteristics

Finished TPU products have good durability and wear resistance. Polyurethane has high resistance to tearing and resistance to mechanical stress. As a result, it is possible to create long-life and functional parts made of TPU that can be used in high stress and demanding environments.

Physical properties

- Specific weight 1.16

- Melting point (according to DSK) 192 °C

- Glass transition (according to DSK) -31 °C

Printing process properties

- Print mode 1 pass

- Layer thickness 100 µm

- Layer printing time 9.5 s

- Printing time with full loading of working area 11 h

Physical characteristics on X axis

- Hardness (5 s, Shore A) 88 ± 3

- Abrasive volume loss 120 mm3

- Tensile strength 10.5 MPa

- Relative elongation at break 185%

- Shrinkage in compression 31%

Physical characteristics on Z axis

- Hardness (5 s, Shore A) 88 ± 3

- Abrasive volume loss 110 mm3

- Tensile strength 6.5 MPa

- Relative elongation at break 55 %

Electrical characteristics

- Surface resistance 1.8 x 1011 Ω

- Volume resistivity 8.9 x 1010 Ω

Dimensional tolerances

- Nominal < 80 mm in X/Y axes < ± 0,6 mm

- Nominal < 80 mm in Z axis < ± 1,8 mm

- Nominal > 80 mm in X/Y axes < ± 1.0%

- Nominal > 80 mm in Z axis < ± 2.0%

Resilient and resistant to chemistry

Industry uses TPU powder for 3D printing as it is a resilient material that enables the creation of finished products with the characteristics of high flexibility and elasticity. In addition, TPU products with high strength can withstand deformation without parts breaking and return to their original shape.

Polyurethane also has good resistance to various chemicals, including oils, solvents, and some acids. This allows TPU finished products to be used in manufacturing where chemical resistance is required.

| Liquid | Resistance |

|---|---|

| Diluted alkaloids | ●●●●● |

| Concentrated alkaloids | ●●●●● |

| Hot water | ●●●○○ |

| Chloride salts | ●●●●● |

| Alcohol | ●●●●● |

| Esters | ●●●●● |

| Ethers | ●●●●● |

| Ketones | ●●●●● |

| Aliphatic hydrocarbons (including gasoline constituents) | ●●●●● |

| Motor oil | ●●●●● |

| Aromatic hydrocarbons | ●●●●● |

| Toluene | ●●●●● |

| Unleaded gasoline | ●●●●● |

| Brake fluid | ●●●●● |

| Chlorinated hydrocarbons | ●●●○○ |

| Trichloroethylene | ●●●○○ |

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you