PP (polypropylene) for 3D printing

HP 3D polypropylene (PP) is a material designed for 3D printing using HP’s Multi Jet Fusion technology, based on thermoplastic polypropylene. The low density and minimal moisture absorption of PP, in addition to its chemical resistance, are just some of its outstanding qualities.

3D printing with PP is ideal because the high isotropic mechanical properties of polypropylene means that: printed parts have the same strength throughout their entire volume. As a result of this quality, functional prototypes made of polypropylene, as well as PP fixtures and components can all be successfully produced.

Where the material is used

The non-flammable 3D printing PP material has a high chemical resistance, so it does not change its properties when interacting with various chemicals or materials.

-

Automobile industry

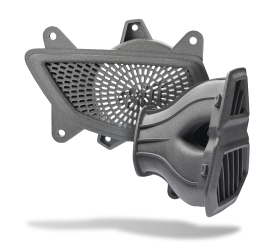

The material is used to create functional polypropylene prototypes of automobile parts, such as fairings, instrument panels, ventilation grilles and internal components. The PP filament’s properties allow the final products to withstand the required loads and chemical influences.

-

Electronics

3D printing with PP can be used to create enclosures and fasteners for electronic devices, such as panels, connectors, and holders. The chemical resistance of PP for electronics and device enclosures ensures that components will be protected from external factors.

-

Industrial manufacturing

PP is useful for creating fixtures, tools, and parts for industrial manufacturing. Functional PP prototypes have sufficient strength and durability to withstand the demands of the manufacturing environment.

-

Packaging

3D printing using HP 3D polypropylene is used to produce boxes, containers, lids, and pallets. PP has sufficient strength and resistance to external influences to make it suitable for use in the transportation and storage of goods.

High physical characteristics

Products made of PP have a gray coloured surface. The layers of this material are thoroughly sintered, making the final products strong and highly resistant to abrasion.

General properties

- Powder melting point 138° C/ 280° F

- Particle size 62 µm

- Bulk density of powder 0,34 g/cm³

Physical characteristics

- Natural color grey

- Max workable size 250 x 250 x 250 mm

- Minimum tolerance ±0,60 mm below 100 mm ±0,6% above 100 mm

- HDT @ 0,45 MPa 100 °C

- HDT @ 1,8 MPa 60 °C

Resistant to water and chemicals

Because PP products have a non-porous structure, they do not need to be impregnated with epoxy resins. The material can be used to print pipelines and hermetically sealed containers.

The properties of PP end-use products and fixtures will be preserved after long periods of contact with chemicals. Parts will be durable even when interacting with greases, solvent, gasoline and alkaline media.

| Liquid | Resistance |

|---|---|

| Diluted alkaloids | ●●●●● |

| Concentrated alkaloids | ●●●●● |

| Hot water | ●●●○○ |

| Chloride salts | ●●●●● |

| Alcohol | ●●●●● |

| Esters | ●●●●● |

| Ethers | |

| Ketones | ●●●●● |

| Aliphatic hydrocarbons (including gasoline constituents) | ●●●●● |

| Motor oil | ●●●●● |

| Aromatic hydrocarbons | ●●●●● |

| Toluene | ●●●●● |

| Unleaded gasoline | ●●●●● |

| Brake fluid | ●●●●● |

| Chlorinated hydrocarbons | ●●●○○ |

| Trichloroethylene | ●●●○○ |

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you