Orthopedic insoles

-

Customer:

private manufacturer of insoles and prostheses

-

Model:

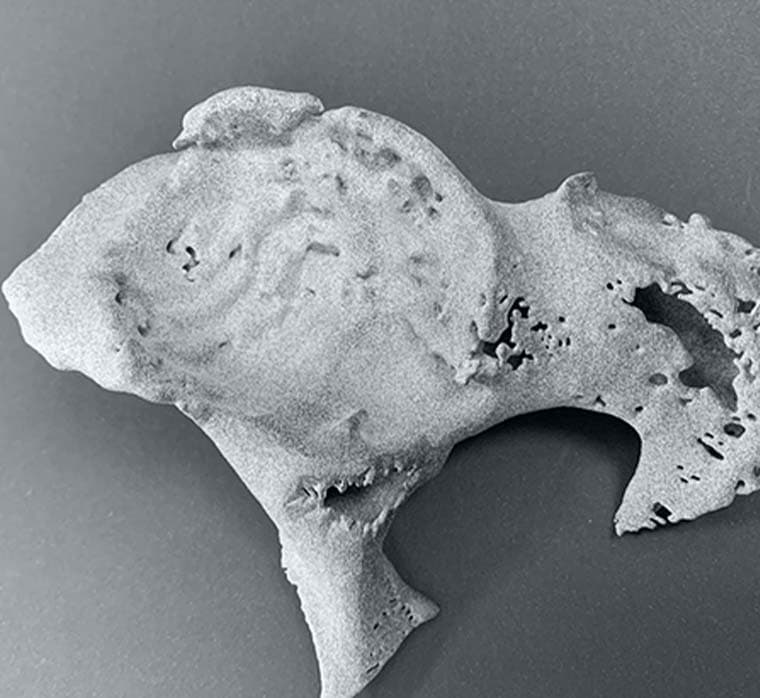

orthopedic insoles

-

Weight:

(3 pcs) 75 g each

Customer’s problem

The customer had to test models of insoles to start his production. The finished product was required to be lightweight, flexible, and durable. The customer used different types of 3D printing to produce the prototype, but none of them gave the required quality and accuracy. The products were printed from hard thermoplastics, which fractured and crumbled under load.

Problem solution

The customer turned to Infomir 3D Printing for help as it uses modern industrial line HP Jet Fusion 5210 for printing. They chose thermoplastic polyurethane (TPU) as the printing material: it is durable, flexible and moisture resistant.

Result

The insoles were printed, sandblasted and sent to the customer within 5 days. The set of finished products met all the required specifications. Thanks to Infomir 3D Printing, the customer got high quality prototypes at a reasonable price.