Services for 3D printing studios

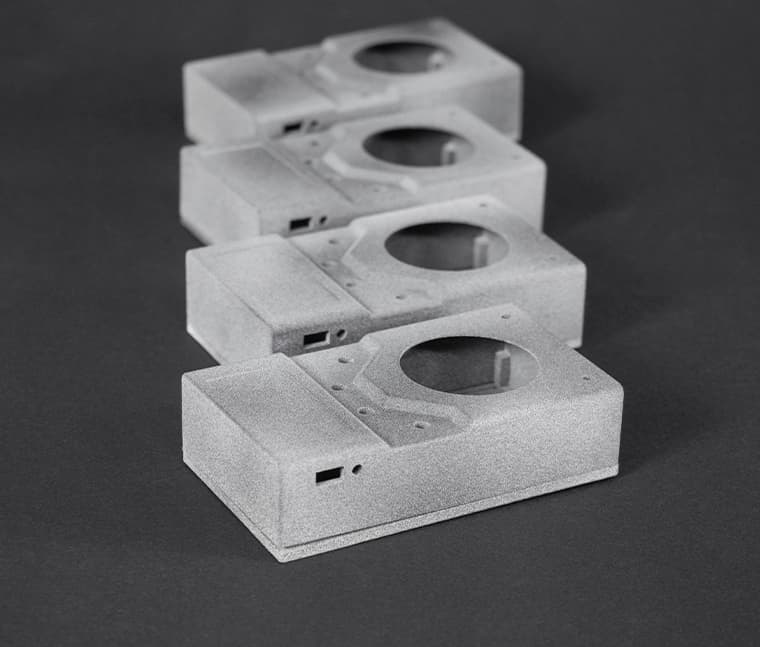

We help with critical orders when products that have been worked out in detail are needed quickly. For printing material, we use HP PA 12 polyamide, polypropylene (PP), and thermoplastic polyurethane (TPU) on the US-developed HP Jet Fusion 5210 line.

How 3D printing studios use MJF Technology

-

Printing complex orders

If the technology of your equipment does not allow you to print products with high precision and repetitive accuracy, use the Infomir 3D print outsource service. This will help you retain your customers and provide them with quality products on time.

-

Fast printing of large batches

The HP Jet Fusion 5210 line can work around the clock. This equipment makes it possible to create products from high-quality plastic that are far from inferior to molded products. Due to high resolution and printing accuracy, the products do not require further processing: after powder residues are removed, they are ready for use.

-

Quick cost calculation

3D printing studios can use the online calculator to check the cost of printing within a few minutes and then inform the customer.

Partners will get a 20% discount on the total order amount

There is a permanent 20% discount for official partners. To get the discount, fill out the form and tell us about your 3D printing studio. Once we have processed your request, you will get a discount on the first and all subsequent orders.

Benefits of Infomir 3D printing

-

01

High print accuracy

Infomir equipment enables the printing of products with the high resolution of 1,200 × 1,200 dots per square inch. Thanks to this print accuracy, it is possible to produce items with a smooth surface that do not require further processing.

-

02

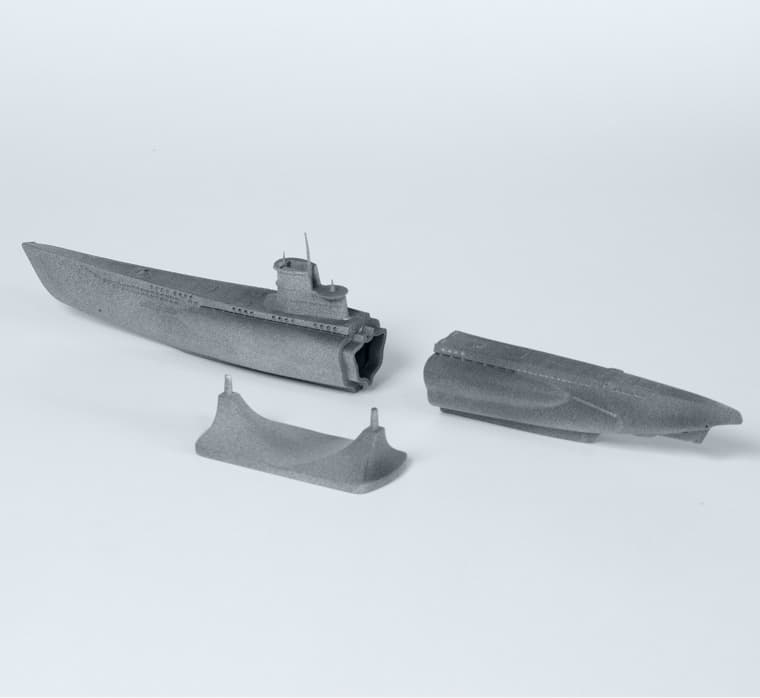

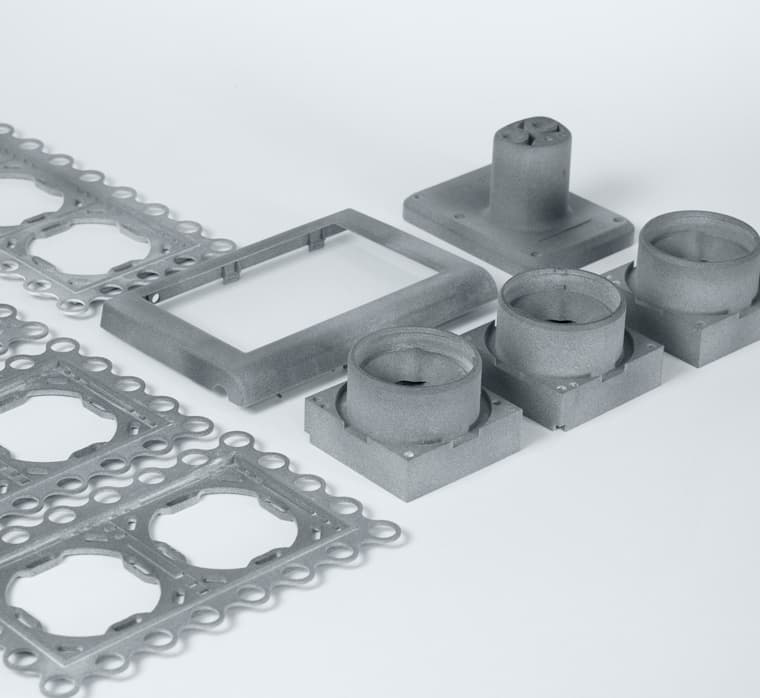

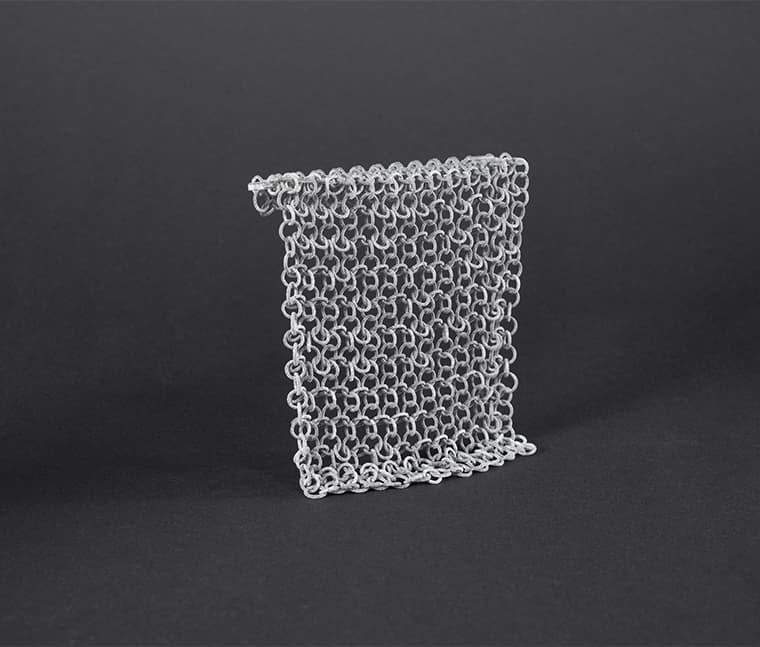

Solid complex structures

With the help of three-dimensional printing, complex structures can be created: hinge joints, chains, and parts within parts based on a box-in-a-box model. They are printed not piece by piece, but at once, thus avoiding the need for gluing or soldering.

-

03

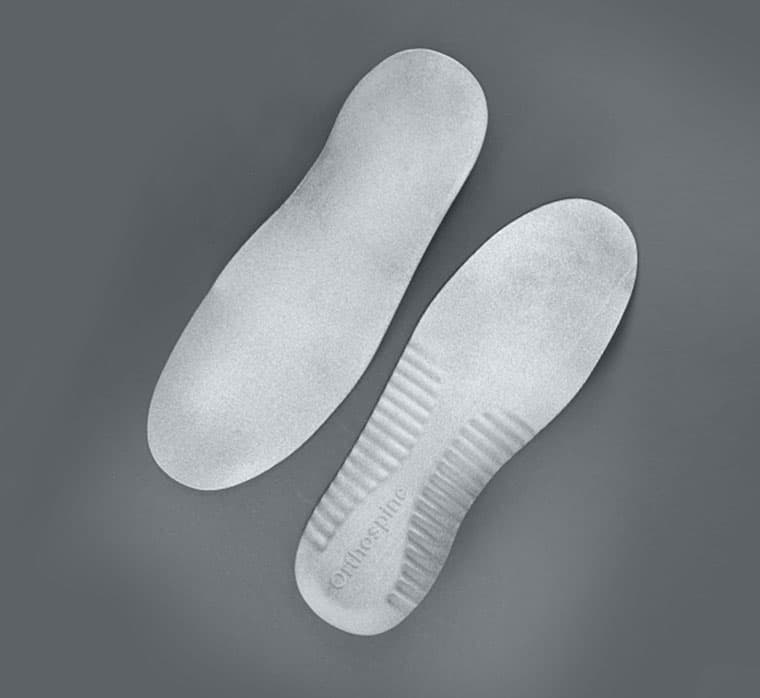

Durable material printing

Infomir makes products from durable, water- and heat-resistant HP PA 12 polyamide, lightweight polypropylene (PP) plastic, and thermoplastic polyurethane (TPU) to create flexible products. These materials are not affected by lubricants, oils, petroleum, gasoline, aliphatic hydrocarbons, and alkalis.

-

04

Printing of products with complex geometry

3D printing allows you to diversify your design by producing items with a smooth, corrugated, porous, or perforated surface. This makes it possible to print lightweight, durable, and hollow structures.

-

05

Post-processing

Printed products have a uniform structure. Such items are easy to process: dye, sand, and putty. They do not crumble, which makes it possible to modify them if necessary: drill, saw, or cut.

-

06

Printing of large-format items

You can use the HP Jet Fusion 5210 print line to produce single-piece products of 380 × 284 × 380 mm in size. Larger items are printed piece by piece. The components are then glued together. The joints are sanded and are unnoticeable in the finished product.

-

07

Demand forecast

You can find out the demand for products by producing a small batch of them. This can help manufacturers estimate the demand for a new product.

-

08

Payback

3D printing is cost-effective even when several items are made. A start-up doesn’t have to invest in an expensive mold. It can get profit from the very first printed batch.

FAQ

-

Do you ship orders internationally?

We offer courier delivery in Odesa and ship by Nova Poshta across Ukraine.

To learn more about shipment to your country, contact our manager by phone or e-mail:

Tel.: +380 (99) 075 59 95

Email: 3dprint@infomir.com -

How long does it take you to fulfill orders?

A printing cycle takes 3–5 days. It includes building, cooling, and sandblasting.

-

What material do you use for 3D printing?

Three materials are used for printing on the HP Jet Fusion 5210 line: HP PA 12 polyamide, polypropylene (PP), and thermoplastic polyurethane (TPU).

HP PA 12 can withstand physical stress and vibration and is resistant to low and high temperatures; products retain their properties and shape under temperature exposure ranging from −50°C to 150°C. The melting point of HP PA 12 is 187°C (for comparison, for ABS plastic, this value is 105°C). This material is used in the automotive and aerospace industries. For more details about the PA 12 polyamide, see the Hewlett Packard document.

PP is the optimal solution for printing lightweight products that are resistant to chemical exposure and water. The bulk density of polypropylene powder is 0.34 g/cm³, which is almost three times less than that of polyamide (1.01 g/cm³). Due to that, polypropylene products are lightweight. The material is suitable for printing device cases, automotive parts, prototypes, etc.

TPU is a material that allows you to print flexible products (flexibility can be adjusted depending on the customer’s tasks). Thermoplastic polyurethane is also moisture- and chemical-resistant, with a powder melting point of 192°C. This material is used in the light and automotive industries, medicine, electronics, and other fields.

When choosing a material, please be aware that the strength of the product depends on its design features and the thickness of its walls. Follow our guidelines on how to prepare models from PP, HP PA 12, and TPU for printing to develop the optimal product model.

-

What are the maximum dimensions?

The printer has a build area of 380 × 284 × 380 mm.

If the model is larger than that, it is divided into parts and then assembled. This is how car bumpers and dashboards, architectural models, and sculptures are created. Our online calculator doesn’t divide models into parts, so only project managers can adequately assess the build price in such cases.

Send your oversized models to our manager:

Tel.: +38 (099) 075 59 95Telegram: https://t.me/infomir3dprinting

Email: 3dprint@infomir.com

-

How precise is MJF printing?

The HP Jet Fusion 5210 applies polymer in layers of 0.08 mm with a horizontal resolution of 1,200 × 1,200 DPI and a margin of error of 0.08–0.1 mm.

The horizontal resolution is based on the maximum precision of the X- and Y-axis movement of the printhead. The higher the number, the higher the level of detail. Vertical resolution is the minimum thickness of the polymer layer applied in one pass. The thinner the layer, the smoother the build’s surface is.

-

Do you do post-processing?

The completed builds only undergo sandblasting to remove surplus polymer. Optionally, they can also be colored.

We use two coloring methods:

- Dyeing. The application of color by immersing the item into a reservoir of dye.

- Graphite blasting. Similar to sandblasting, but with glass and graphite as an abrasive material. It gives the item a dark-gray color.

Dyeing and blasting are inexpensive and efficient ways of getting a high-quality finish.

Available colors: graphite, black, and gray. Other finishes will soon be made available. -

How do I pay for my order?

You can pay for your order once our manager clarifies all the details with you. Infomir 3D Printing fulfills orders only on pre-paid terms. You can pay for your order with a PrivatBank card or cashless payment.

For cashless payments, we need the client to submit their registration certificate, VAT payer’s certificate, and banking details. After the order is paid for, we will deliver the finished items together with an invoice.

Order 3D printing

-

1. Upload your 3D model

-

2. Specify the quantity and color

-

3. Pay the order

-

4. We print the product

-

5. The order is shipped directly to you