Startup Elliscope: unmanned airship as the future of aeronautics

To pitch projects to investors, startups should not only spell out the benefits and business calculations, but also showcase the final product’s prototype or mockup. In the early stages, it is not always possible to create a product in a quick, workmanlike, and cost-effective manner—the chain of logistical processes is still to be established, while the project itself has yet to begin yielding any profit.

The case of the Ukrainian startup Elliscope will tell you how the use of additive technologies enables companies to quickly and cost-effectively prepare visual samples for their presentations.

About Elliscope

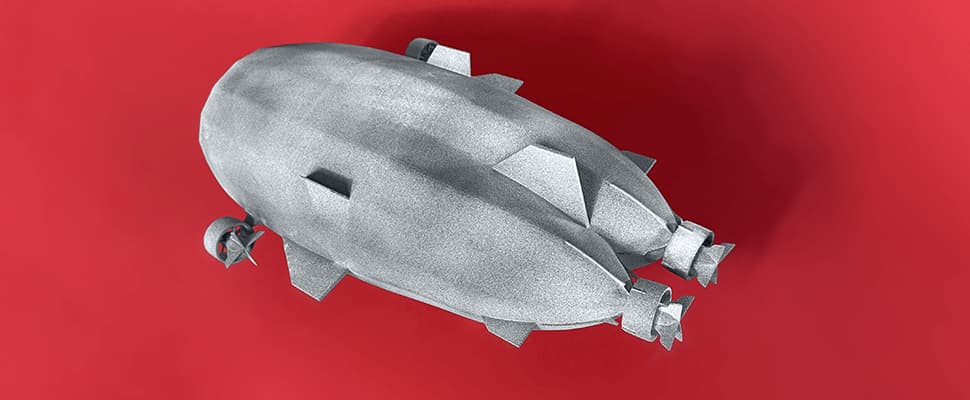

The Elliscope team designs and develops the Aeronium airship, a hybrid aircraft. Device dimensions are 15x4x4 m. The device can move at a speed of 150 km/h at an altitude of up to 22 kilometers and operate for 3 weeks without refueling.

The device is designed to scan terrain and survey the areas to obtain data for analytics. In addition, the airship can be used for other purposes: broadcasting radio signals or transporting cargo.

Aeronium will receive all of the tasks from the Flight Control Center and complete them in an offline mode. There is no need for someone to be present at the airship location.

How the startup began

Right from the start, the Elliscope team has consisted of four people: Alexey Belochenko (CEO & founder), Vladislav Stasiuk (COO & co-founder), Dmitriy Blazhevskiy (Solution Architect), and Aleksandr Rozin (Head of Engineering). The team consists of mathematicians, engineers, and programmers. The idea for the manufacture of a global airship came in 2019 during joint participation in the NASA Space Apps Challenge hackathon. They planned to use the UAVs to fight forest fires. Later on, the developers realized that Aeronium airships could be used for other purposes as well.

The team started working on the technical aspects of the issue and planning the business model. They were developing the software, calculating the physical characteristics, and designing the prototype of their device. The process was going smoothly and confidently thanks to the team’s knowledge of math, physics, and programming. As a result, Elliscope was invited to join the largest IT conference in Europe—Web Summit—where the team presented its project and received helpful feedback from participants, and several inquiries from investors.

3D printing use

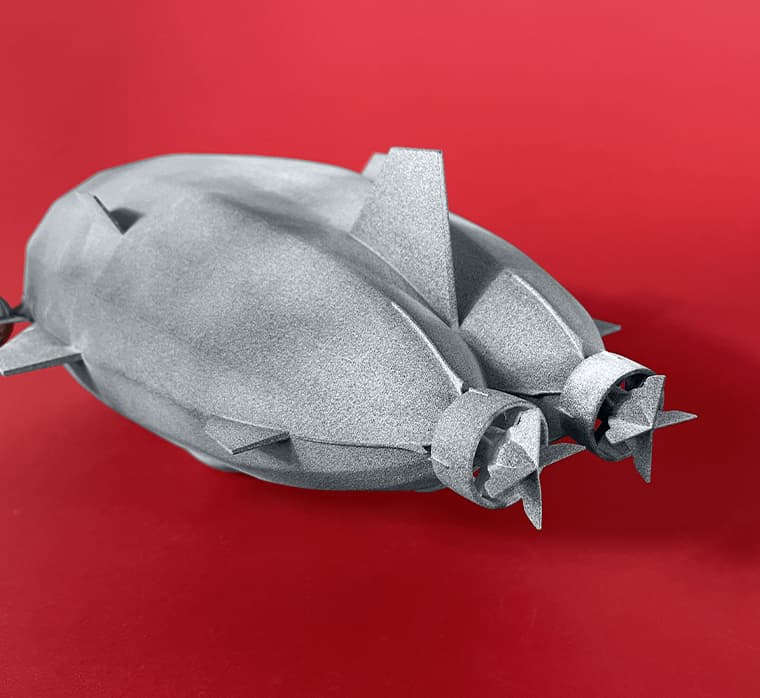

The Elliscope team needed to make an airship mockup to demonstrate their product at Web Summit. The prototype casting method was not suitable because of the time and cost of making the mold. Instead, they decided to print it on a 3D printer, but the FDM technology did not work out as the printed product was of poor quality and fragile. The mockup comprised some complex elements that simply could not be replicated using FDM printing.

Elliscope turned to Infomir 3D Printing for help to print the airship model using the MJF printing technology. The order was completed within a few days. The finished product turned out to be robust, solid, and with highly detailed small elements.

We transported the UAV prototype across Europe and did not notice a single flaw. The prototype withstood severe loads and had no damage. We were thrilled with this result!

The specialists at Infomir 3D Printing are always open to cooperation and very sociable. The fastest and highest quality printing possible.

Dmitriy Blazhevskiy,

Elliscope, Digital Solutions Architect

During the manufacturing phase of prototypes, Elliscope plans to use 3D printing to fabricate static parts that will not be subject to temperature stresses. The printing material allows for the making of strong and lightweight products, which is vital for aircraft.

Plans to use the Elliscope airships

Elliscope intends to launch its first pilot Aeronium Junior by the end of 2022. The device must reach an altitude of 1 km and have a carrying capacity of more than 100 kg. Once the prototype passes the first tests, the company will manufacture a full-size airship with a carrying capacity of 3 tons and a maximum flight altitude of 22 km.

The airships can be used in the following domains:

- Agro-industry—the devices will be collecting information about fields, soil, and crops.

- Infrastructure scanning—from cracks in buildings to the lengths of roads.

- Retransmitting radio signals—establishing coverage for communication in hard-to-reach areas.

- Transporting cargo—the cargo can be shipped hundreds of kilometers away.

Since the COVID-19 pandemic began, many holding companies and farmers have been interested in our project. Since then and up to this day, we have felt the support of the market and know for sure that we are doing everything just right!

Dmitriy Blazhevskiy,

Elliscope, Digital Solutions Architect

The startup has only been working on the product for three years and plans to roll out the first working prototype in 2022. Among other benefits, 3D printing using the MJF technology helped implement this large-scale project in a short period. Infomir 3D Printing is always happy to cooperate with interesting and aspiring startups. More detailed cases of such projects are available in our Portfolio section .