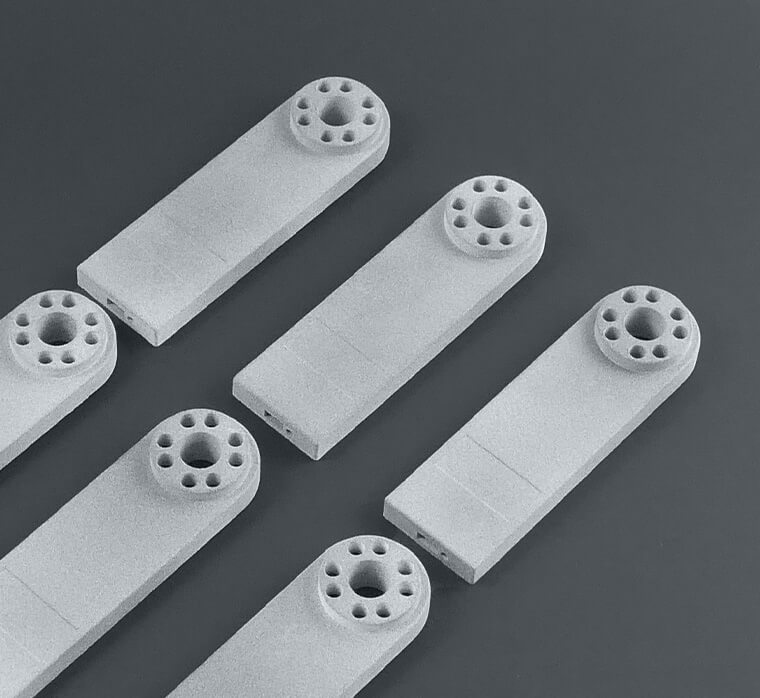

QR code readers

-

Client’s website:

-

Model:

casing parts for QR code readers

-

Weight:

50g

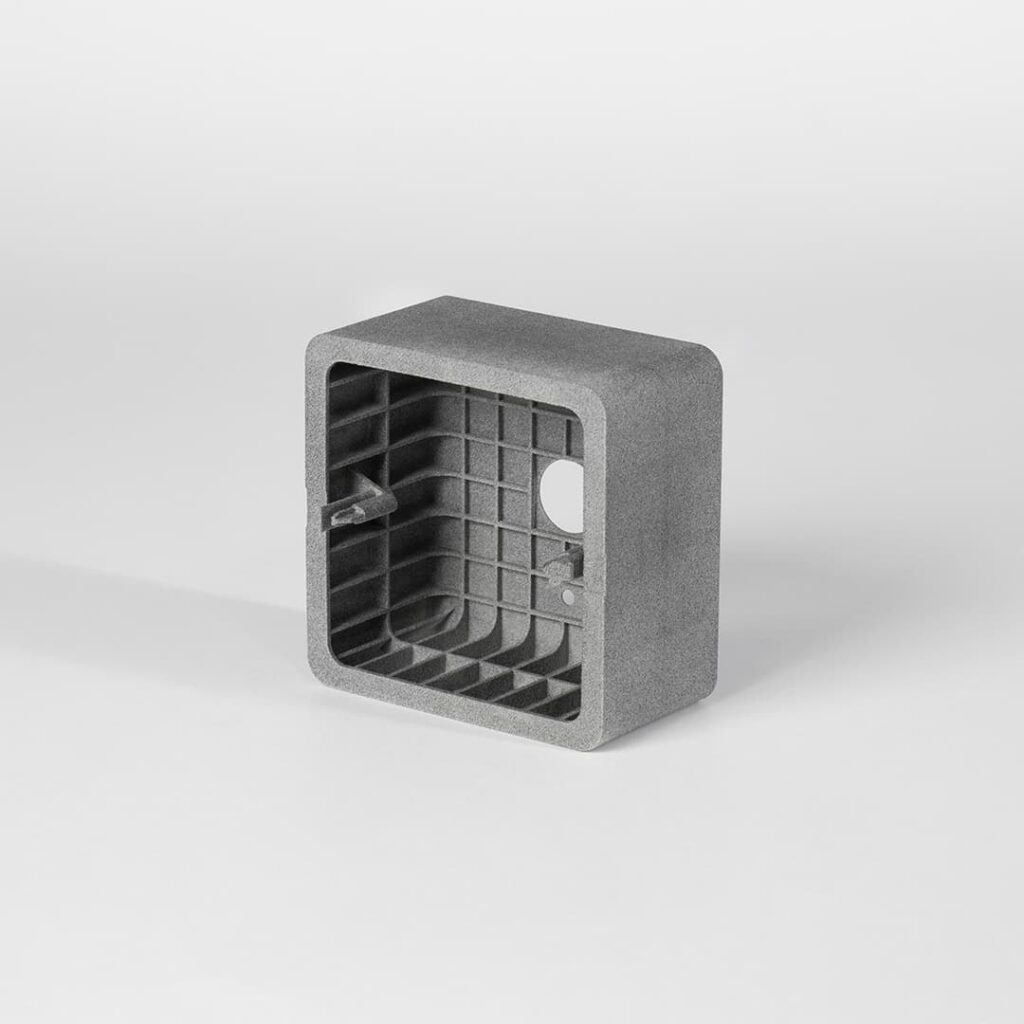

To ensure their customers enjoy convenient navigation, the photo studio Kupol Space has implemented an electronic reader. The device reads a QR code and generates an easy route for users, showing the elevator routing pattern and the corridors in the building. However, the studio staff needed to manufacture an additional plastic part to upgrade the device.

Client’s Problem

The client didn’t see casting as an option because the technology would have required disproportionate investment, while manufacturing a mold would have taken several months. For these reasons, the photo studio chose 3D printing.

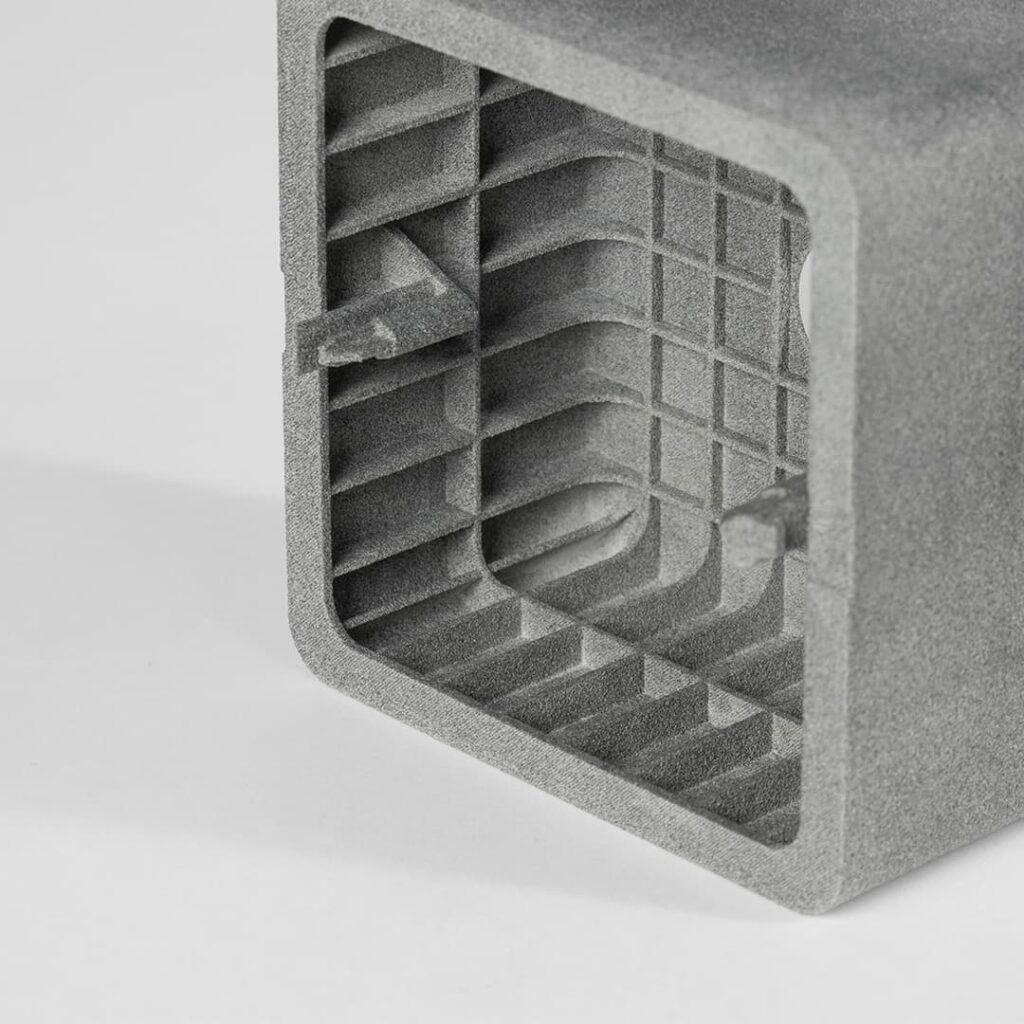

FDM technology didn’t fit the requirements as the product couldn’t offer high enough quality. After consideration, the photo studio staff settled on Multi Jet Fusion technology that allows them to print a durable, single, and small product at an affordable price.

Client’s Solution

Developing a 3D model is the first step in this process – you can start printing after that has been completed.

For this task the photo studio staff contacted Infomir 3D Printing. The client didn’t have any drawings and let our designer develop the model based only on their idea. When the 3D model was ready, we printed the product using the HP Multi Jet Fusion 5210 system.

Result

The photo studio received the necessary part that perfectly matched the shape and physical specifications within seven business days. As a result, it successfully attracted more visitors and boosted customer loyalty.